Technical Details & Capabilities:

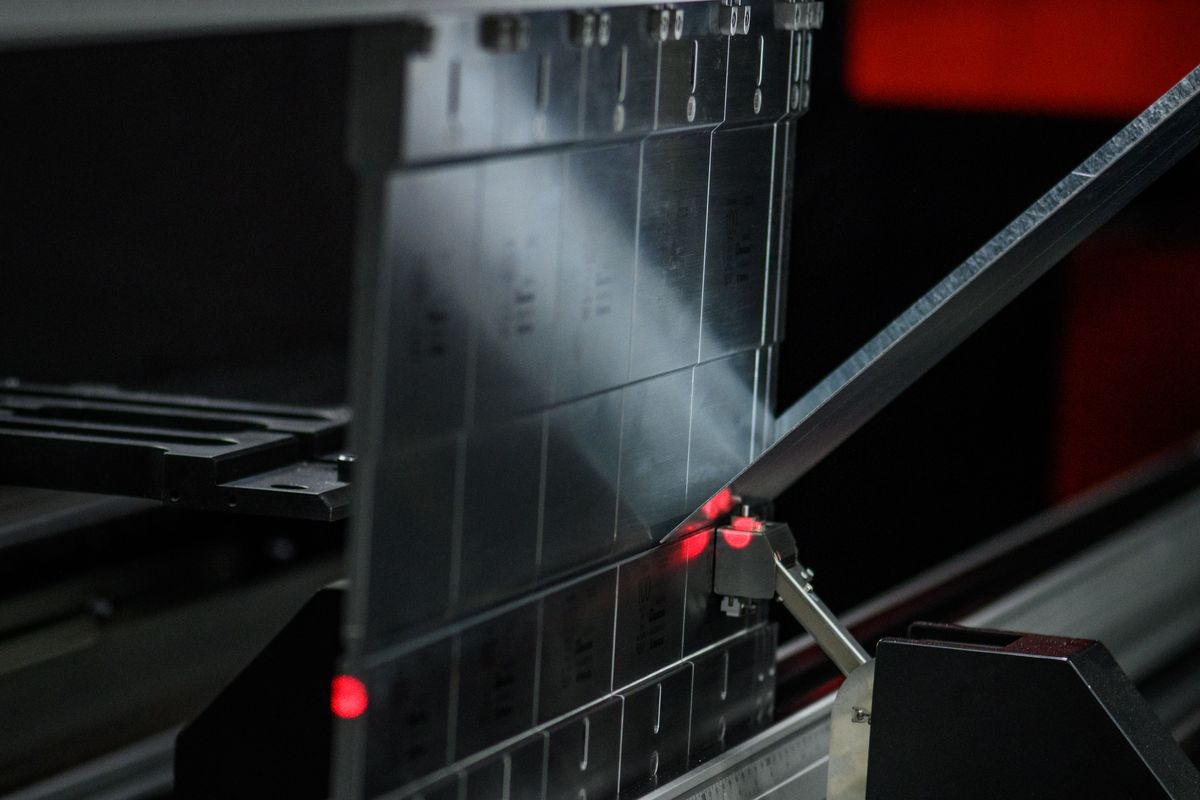

High-precision press beam drive

Outstanding angular bending accuracy

Constant, accurate bending angles

Motor-operated foot pedal

Precise, uniform bending is guaranteed along the entire length of the press beam

Outstanding angular bending accuracy

Constant, accurate bending angles

Motor-operated foot pedal

Precise, uniform bending is guaranteed along the entire length of the press beam

TDS: detection of the thickness of the sheet material (discrepancies between the thickness determined and a previously specified reference value are detected the entry depth of the die is adjusted)

Automatic angle adjustment

Highly accurate bending

For changing material thickness and properties

No need for test bending and adjustment of the initial bend angle

Highly accurate bending

For changing material thickness and properties

No need for test bending and adjustment of the initial bend angle

Press force = 1000 kN

Bending length = 3110 mm

Abkant Drive = Servo-Hydraulic

Distance between side frames = 2700 mm

Stroke = 250 mm

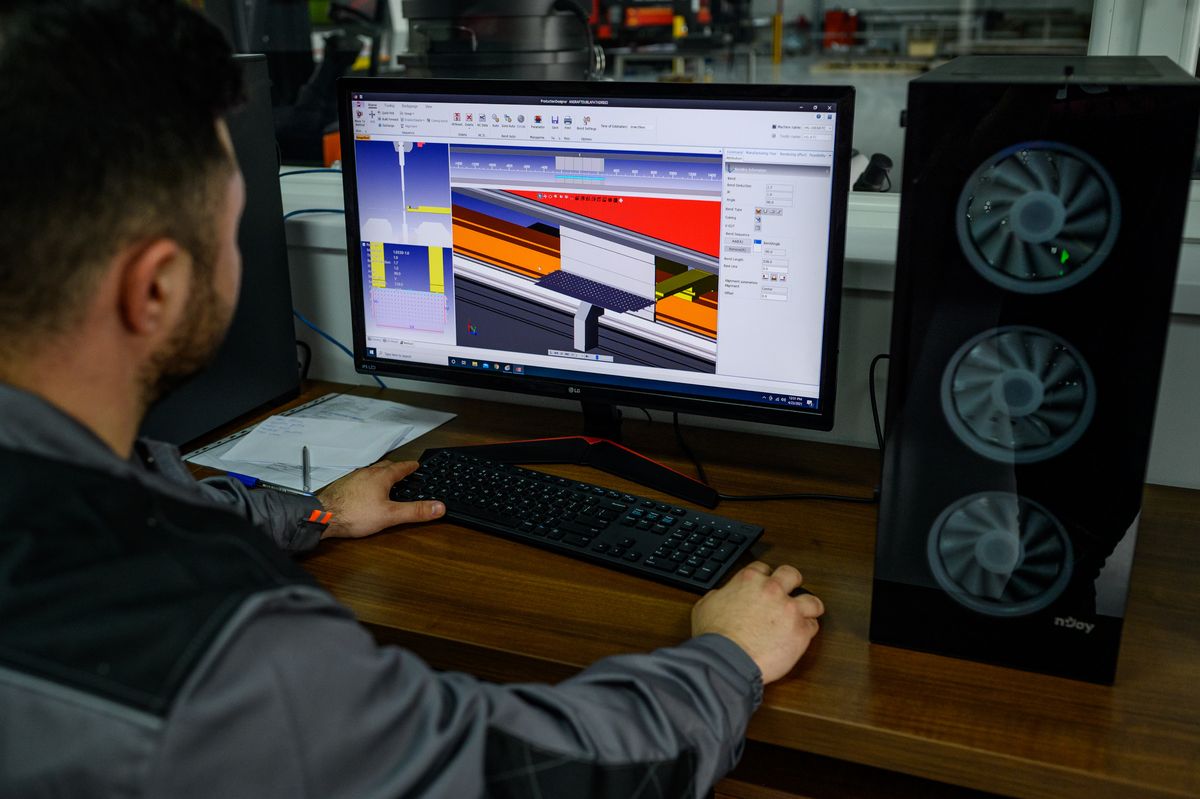

Hybrid Bending Machine with Automatic Tool Changer

Pioneering technology for prototyping, small lot sizes and high variety of parts - maximum machine utilization by minimizing set-up times.

In the sheet metal processing a variety of parts and small quantities are required. To successfully meet this requirement, AMADA exemplifies the HG ATC Series - the combination of a servo-hydraulic press brake with automatic tool changer.

AMADA HG-100.3 ATC Servo-Hydraulic Press-Brake

Metalworks Babadag

Newsletter

If you want to stay in touch with our latest news and special offers, please subscribe